+8618206021758 jenkin@hualongm.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

HKNC-500

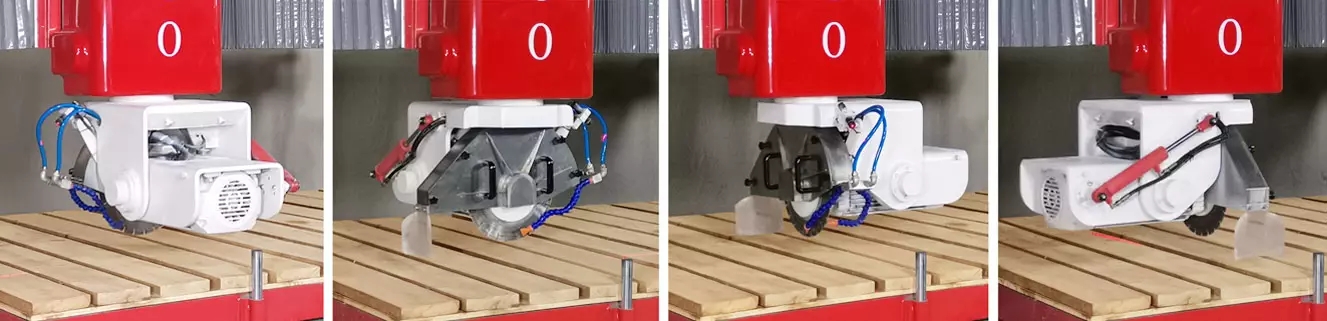

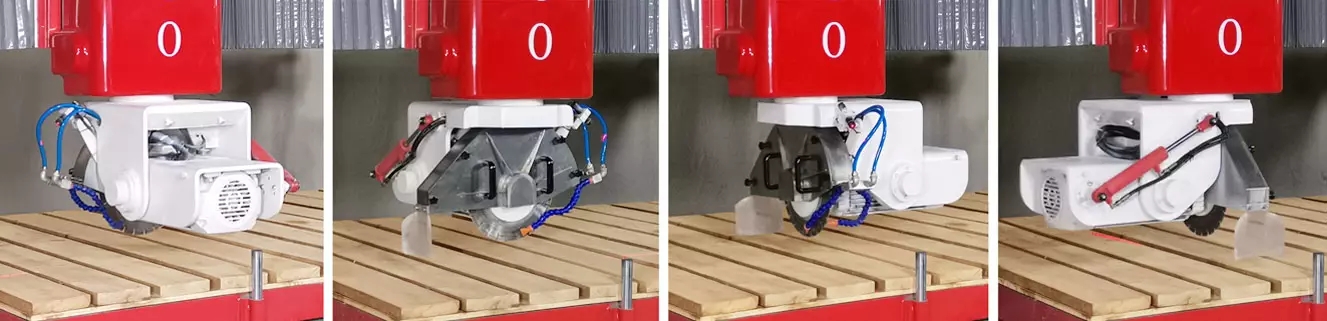

The introduction of the HKNC-500, a high-end CNC machine cut stone system from Hualong Machinery. This cutting-edge technology, featuring an Italian control system called ESA, provides a touch screen interface that is easy to set up and automatically processes. With its high productivity and accuracy, it reduces the complexity of the most difficult machining tasks, and always provides effective results. The HKNC-500 has digitalomotors that are provided by ESA, these digitalomotors are reliable in controlling the X, Y, Z, and C axes. These combined drives provide a total digital association with the CNC system, which enhances performance and accuracy. To assist with the placement of the cuts, the machine is equipped with a laser-based reticule system from China. This laser-based instrument that checks for accuracy and ensures precise placement during the cutting process is called a caliper. The machine's electro-spindles, which are controlled by an inverter, have a range of speeds that is adjustable from 0 to 6000 RPM. This versatility is beneficial because it allows the use of various instruments, including blades and diamond instruments like core drills or milling cutters. The method of changing the tool is manual, this method provides flexibility and convenience. Hualong Machinery's stable performance is enhanced by the inclusion of electric components derived from recognized brands like ESA, Schneider, and Sanch. For superior precision and long durability, the HKNC-500 employs Hiwin linear followers from Taiwan, China. These celebrated products are utilized on the crossbeam and carling, which guarantees a long lifespan and high accuracy cutting. Experience the superiority of the HKNC-500, the ultimate slab cutter, this machine is designed to revolutionize the stone industry.

TECHNICAL DATA FOR HKNC-500 | ||

Diameter of saw blade | ø400-ø500 | mm |

Dimension of working platform | 3300x2000 | mm |

Max. cutting length | 3300 | mm |

Max. cutting thickness | 140 | mm |

Max. lifting stroke | 250 | mm |

Max. lifting weight by sunction cups | 200 | kg |

Power of main motor | 11 | kw |

Power of cutter frame reciproctating motor | 2 | kw |

Power of crossbeam shifting motor | 1.1 | kw |

Power of hydraulic station motor | 2.2 | kw |

Power of lifting motor | 0.85 | kw |

Gross power | 16 | kw |

Water consumption | 2 | m3/h |

Gross weight | 5400 | kg |

Dimensions (L x W x H) | 5700x3260x2765 | mm |

1. Four-axis interpolation and one-axis electronic control with the Italian CNC Esa system that is precise and effective in slab cutting.

2. User-friendly interface that uses a 19" color touch screen, this interface is simple to use and control.

3. The blade's rotation range is 0°-360° and its tilt is 90°, which enables the blade to cut in any direction and at any angle.

4. The platform's working area can be as wide as 85 degrees, this facilitates the easy loading of slabs onto the machine.

5. Monoblock design that is sized for transportation in containers, this design ensures easy loading, unloading, and installation.

6. A manual option is available for users who require simple cuts.

7. Nesting function, either manual or automatic, that facilitates the greatest utilization of the slab's surface area.

8. Vacuum system that can be adjusted to different levels of automation for efficient piece handling.

9. Optional photo slab option that provides precise placement and avoids defects.

10. Opcionality of matching veins for a seamless transition between colors and veins on your project.

1. Versatile Capabilities: The HKNC-500 possesses a variety of cutting capabilities, including vertical, inclined, and horizontal cuts, as well as contour cutting. It is even capable of undertaking intricate tasks like sinking, profiling, and engraving, which makes it appropriate for use in a variety of stone and ceramic projects.

2. Advanced CNC System: This system is equipped with the Italian ESA CNC system, this system provides precise and efficient control, which results in high quality cuts and shapes. The user-friendly 19" color screen with a touch of a button enables easy setup and control.

3. Flexible Manipulation of the Blade: The machine's blade can rotate around 360 degrees and tilt by 90 degrees, this allows for the chamfering of any direction and any angle. This flexibility is important for achieving intricate designs and exact cuts.

4. Easy Charging and Unloading: The machine's design, which has a tilting platform that is 85 degrees wide and a monoblock that is suitable for transportation in containers, promotes easy installation of slabs, this increases the overall efficiency of the machine.

5. Functionalities: The HKNC-500 possesses both manual and automatic capabilities, it can accommodate simple machining tasks as well as more complex automated processes, such as nesting: to maximize the utilization of material.

6. Accessories: Users can augment the machine's capabilities with additional features like a vacuum manipulator that facilitates efficient workpiece handling, a photo system that avoids defects, and a system that matches veins to the fabric.

7. Large Variety of Use: This machine is appropriate for various purposes, including the decoration of 2D surfaces, countertops, stairs, fireplaces, flooring, funeral art, street furniture, and ventilated facades, all of which are versatile for different purposes.

8. High-quality Components: The machine contains top-quality components, such as digital servomotors, a laser-based system for precise placement, electric spindles that are well-known, and linear guides from leading brands like ESA, Hiwin, and more.

9. dependable Performance: With components that are derived from recognized brands and are stable electric components, the machine guarantees consistent and dependable performance over time, which reduces the amount of time spent on downtime and reduces the cost of maintenance.

10. Precision and Life: The utilization of digitalomotors and high-end linear guides in conjunction with the machine's cutting mechanism results in a high degree of precision in the cut and a long lifespan of the machine, which is beneficial to stone processing companies.

1. 2D Decorative Wall Panels: Our CNC machine cut stone, specifically the HKNC-500 model, is beneficial for creating intricate patterns and designs on stone panels used for decorative wall design.

2. Countertops: With our machine that cuts slabs, Hualong Machinery provides a precise and efficient solution to creating custom countertops from various stone types.

3. Doorsteps, Staircases, and Thresholds: Our CNC machine cut stone has a precise and clean cut, which is ideal for crafting doorsteps, staircases, and thresholds that require exact dimensions and smooth surfaces.

4. Fireplaces: Our automatic stone bridge machine, including the HKNC-500 model, can create beautiful, custom stone pieces for your fireplace that will enhance the focal point of any space.

5. Floorstep: Hualong Machinery's marble machine for cutting stone slabs with a high degree of precision is ideal for creating a durable and attractive stone floor.

6. Funerary Art: Our CNC machine cut stone is commonly utilized in the creation of intricate, personalized artwork regarding funerary matters, this stone allows for the precise carving and shape of memorial stones and monuments.

7. Street Furniture: Our machine stone used in the production of street furniture like benches, fountains, and sculptures is also utilized in the production of these items, which ensures the longevity and aesthetic value of these installations.

8. Ventilated Facades: The machine's capacity to cut stone slabs to a desired thickness and shape makes it ideal for creating ventilated facades that enhance the design of buildings.

The introduction of the HKNC-500, a high-end CNC machine cut stone system from Hualong Machinery. This cutting-edge technology, featuring an Italian control system called ESA, provides a touch screen interface that is easy to set up and automatically processes. With its high productivity and accuracy, it reduces the complexity of the most difficult machining tasks, and always provides effective results. The HKNC-500 has digitalomotors that are provided by ESA, these digitalomotors are reliable in controlling the X, Y, Z, and C axes. These combined drives provide a total digital association with the CNC system, which enhances performance and accuracy. To assist with the placement of the cuts, the machine is equipped with a laser-based reticule system from China. This laser-based instrument that checks for accuracy and ensures precise placement during the cutting process is called a caliper. The machine's electro-spindles, which are controlled by an inverter, have a range of speeds that is adjustable from 0 to 6000 RPM. This versatility is beneficial because it allows the use of various instruments, including blades and diamond instruments like core drills or milling cutters. The method of changing the tool is manual, this method provides flexibility and convenience. Hualong Machinery's stable performance is enhanced by the inclusion of electric components derived from recognized brands like ESA, Schneider, and Sanch. For superior precision and long durability, the HKNC-500 employs Hiwin linear followers from Taiwan, China. These celebrated products are utilized on the crossbeam and carling, which guarantees a long lifespan and high accuracy cutting. Experience the superiority of the HKNC-500, the ultimate slab cutter, this machine is designed to revolutionize the stone industry.

TECHNICAL DATA FOR HKNC-500 | ||

Diameter of saw blade | ø400-ø500 | mm |

Dimension of working platform | 3300x2000 | mm |

Max. cutting length | 3300 | mm |

Max. cutting thickness | 140 | mm |

Max. lifting stroke | 250 | mm |

Max. lifting weight by sunction cups | 200 | kg |

Power of main motor | 11 | kw |

Power of cutter frame reciproctating motor | 2 | kw |

Power of crossbeam shifting motor | 1.1 | kw |

Power of hydraulic station motor | 2.2 | kw |

Power of lifting motor | 0.85 | kw |

Gross power | 16 | kw |

Water consumption | 2 | m3/h |

Gross weight | 5400 | kg |

Dimensions (L x W x H) | 5700x3260x2765 | mm |

1. Four-axis interpolation and one-axis electronic control with the Italian CNC Esa system that is precise and effective in slab cutting.

2. User-friendly interface that uses a 19" color touch screen, this interface is simple to use and control.

3. The blade's rotation range is 0°-360° and its tilt is 90°, which enables the blade to cut in any direction and at any angle.

4. The platform's working area can be as wide as 85 degrees, this facilitates the easy loading of slabs onto the machine.

5. Monoblock design that is sized for transportation in containers, this design ensures easy loading, unloading, and installation.

6. A manual option is available for users who require simple cuts.

7. Nesting function, either manual or automatic, that facilitates the greatest utilization of the slab's surface area.

8. Vacuum system that can be adjusted to different levels of automation for efficient piece handling.

9. Optional photo slab option that provides precise placement and avoids defects.

10. Opcionality of matching veins for a seamless transition between colors and veins on your project.

1. Versatile Capabilities: The HKNC-500 possesses a variety of cutting capabilities, including vertical, inclined, and horizontal cuts, as well as contour cutting. It is even capable of undertaking intricate tasks like sinking, profiling, and engraving, which makes it appropriate for use in a variety of stone and ceramic projects.

2. Advanced CNC System: This system is equipped with the Italian ESA CNC system, this system provides precise and efficient control, which results in high quality cuts and shapes. The user-friendly 19" color screen with a touch of a button enables easy setup and control.

3. Flexible Manipulation of the Blade: The machine's blade can rotate around 360 degrees and tilt by 90 degrees, this allows for the chamfering of any direction and any angle. This flexibility is important for achieving intricate designs and exact cuts.

4. Easy Charging and Unloading: The machine's design, which has a tilting platform that is 85 degrees wide and a monoblock that is suitable for transportation in containers, promotes easy installation of slabs, this increases the overall efficiency of the machine.

5. Functionalities: The HKNC-500 possesses both manual and automatic capabilities, it can accommodate simple machining tasks as well as more complex automated processes, such as nesting: to maximize the utilization of material.

6. Accessories: Users can augment the machine's capabilities with additional features like a vacuum manipulator that facilitates efficient workpiece handling, a photo system that avoids defects, and a system that matches veins to the fabric.

7. Large Variety of Use: This machine is appropriate for various purposes, including the decoration of 2D surfaces, countertops, stairs, fireplaces, flooring, funeral art, street furniture, and ventilated facades, all of which are versatile for different purposes.

8. High-quality Components: The machine contains top-quality components, such as digital servomotors, a laser-based system for precise placement, electric spindles that are well-known, and linear guides from leading brands like ESA, Hiwin, and more.

9. dependable Performance: With components that are derived from recognized brands and are stable electric components, the machine guarantees consistent and dependable performance over time, which reduces the amount of time spent on downtime and reduces the cost of maintenance.

10. Precision and Life: The utilization of digitalomotors and high-end linear guides in conjunction with the machine's cutting mechanism results in a high degree of precision in the cut and a long lifespan of the machine, which is beneficial to stone processing companies.

1. 2D Decorative Wall Panels: Our CNC machine cut stone, specifically the HKNC-500 model, is beneficial for creating intricate patterns and designs on stone panels used for decorative wall design.

2. Countertops: With our machine that cuts slabs, Hualong Machinery provides a precise and efficient solution to creating custom countertops from various stone types.

3. Doorsteps, Staircases, and Thresholds: Our CNC machine cut stone has a precise and clean cut, which is ideal for crafting doorsteps, staircases, and thresholds that require exact dimensions and smooth surfaces.

4. Fireplaces: Our automatic stone bridge machine, including the HKNC-500 model, can create beautiful, custom stone pieces for your fireplace that will enhance the focal point of any space.

5. Floorstep: Hualong Machinery's marble machine for cutting stone slabs with a high degree of precision is ideal for creating a durable and attractive stone floor.

6. Funerary Art: Our CNC machine cut stone is commonly utilized in the creation of intricate, personalized artwork regarding funerary matters, this stone allows for the precise carving and shape of memorial stones and monuments.

7. Street Furniture: Our machine stone used in the production of street furniture like benches, fountains, and sculptures is also utilized in the production of these items, which ensures the longevity and aesthetic value of these installations.

8. Ventilated Facades: The machine's capacity to cut stone slabs to a desired thickness and shape makes it ideal for creating ventilated facades that enhance the design of buildings.